As a family business, founded in 1930, we believe success is based upon innovation through the continuous understanding and improvement of our own and our customers' value streams. This philosophy of always being the industry's innovator has translated into unprecedented growth to become the largest machine tool manufacturer of structural steel and plate fabrication equipment in the world today. The graphic below illustrates our focus and commitment to our business partners.

In the 40's we started to extend our innovative technology to the area of machine tools for the fabrication of structural steel - first in the area of mechanical ironworkers and later in the 60's into the area of automated drill, saw and angle lines.

This technology, the first available to the industry, is keeping with our commitment to be the first with innovative new processes for our business partners.

The article, Reinventing Construction Through a Productivity Revolution by McKinsey best states the productivity challenge that our industry faces when compared to the general manufacturing sector of our economy. The basis of this report highlights why it is essential that our mission must be to drive innovation to levels never previously thought to be attainable.

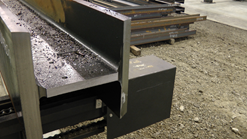

The FICEP inventions explained below are significant firsts, but as you can conclude from the McKinsey article, we are just scratching the surface. Thus our corporate commitment to our partners is to constantly reinvest our profits back into product development to help promote the competiveness of structural steel as well as their businesses.

Listed below are just some on the many innovative industry firsts that have been engineered by FICEP to strengthen the competitiveness of our business partners.